Climate considerations by the flavor operations

Climate

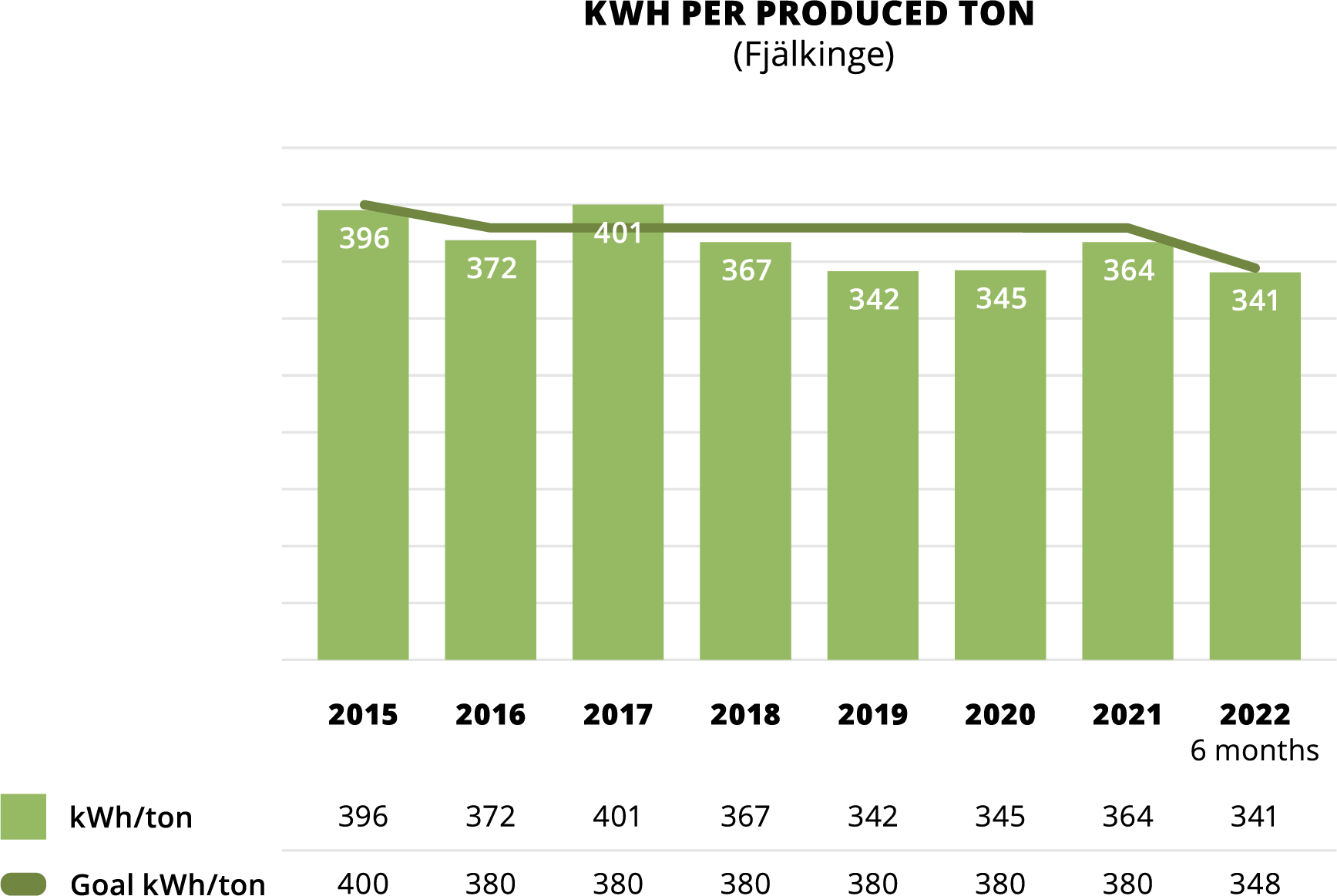

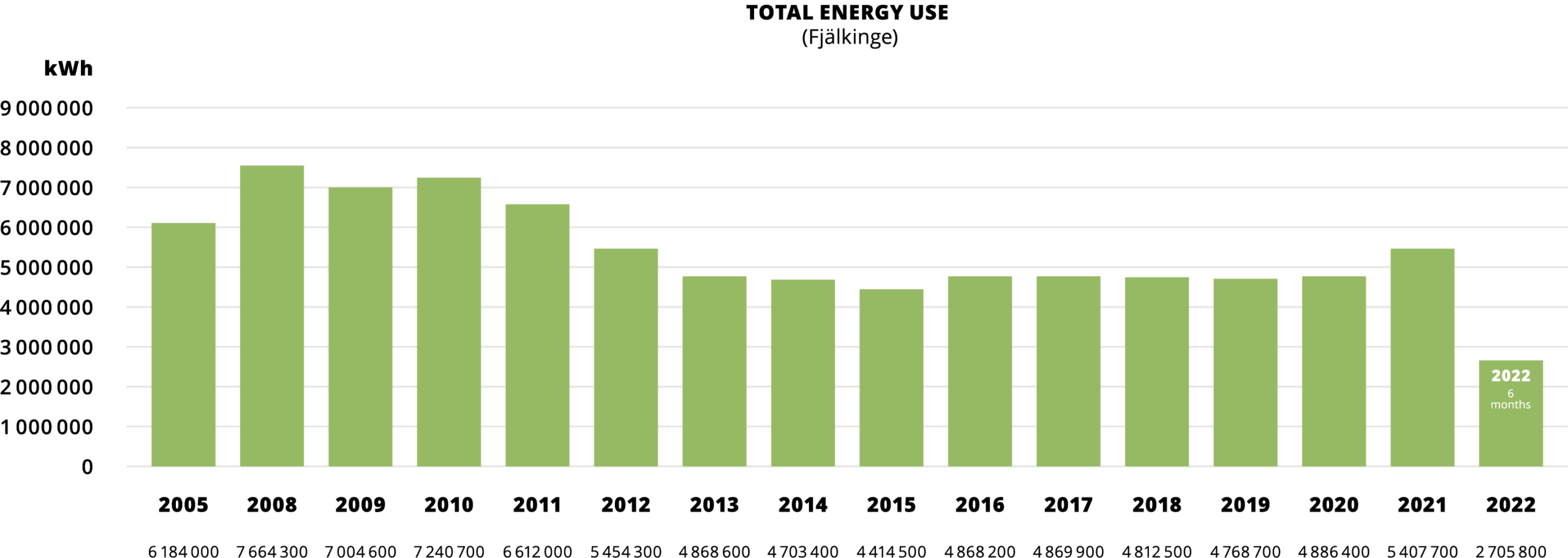

Processing on the flavor side requires much less energy than the starch process, and all the energy we use for our own production in the Fjälkinge factory has been fossil-free since January 2019. Despite this, it is of course important for us to reduce our energy use, and the operation is certified according to ISO 50001. We reached our 2020 energy goal as early as 2019, and for the current year we have set ambitious new targets. By the turn of the year 2022/2023, we intend our energy consumption per tonne of product, at production volumes corresponding to 2017, to be 348 kWh – a reduction of 4% from last year’s result, and a goal we have a good chance of achieving because our energy consumption at the 2022 half year mark was 341 kWh/tonne.

To better understand how our flavor operations affect the climate, in 2022 we have begun to calculate the carbon footprint in Scope 1, 2 and 3 according to the Greenhouse Gas Protocol. The total carbon footprint for Scope 1 and 2 for 2021 was 172 tonnes. Calculations are underway for Scope 3, and from next year onwards we intend to also report and set goals for these parts of our carbon footprint.

We have already begun our work to reduce our climate impact in areas we know are particularly relevant. One of these is our outbound transports to customers across Sweden. For Kockens products, we have signed up to DLF’s Transport Initiative 2025, a voluntary commitment and a clear statement that the grocery industry wants to drive development towards fossil-free transports. This means that we have a goal of fossil-free transports for Kockens products from 2025. During the year, we have also launched several Kockens products with redesigned packaging with a lower carbon footprint. Read more on page 66.

We have also joined the Swedish Food Federation’s Sustainability Manifesto, where one of the five commitments is “A fossil-free industry”. In line with this manifesto, we are aiming to use only fossil-free fuels for transports of Culinar products by 2030.

MATERIAL RECYCLING

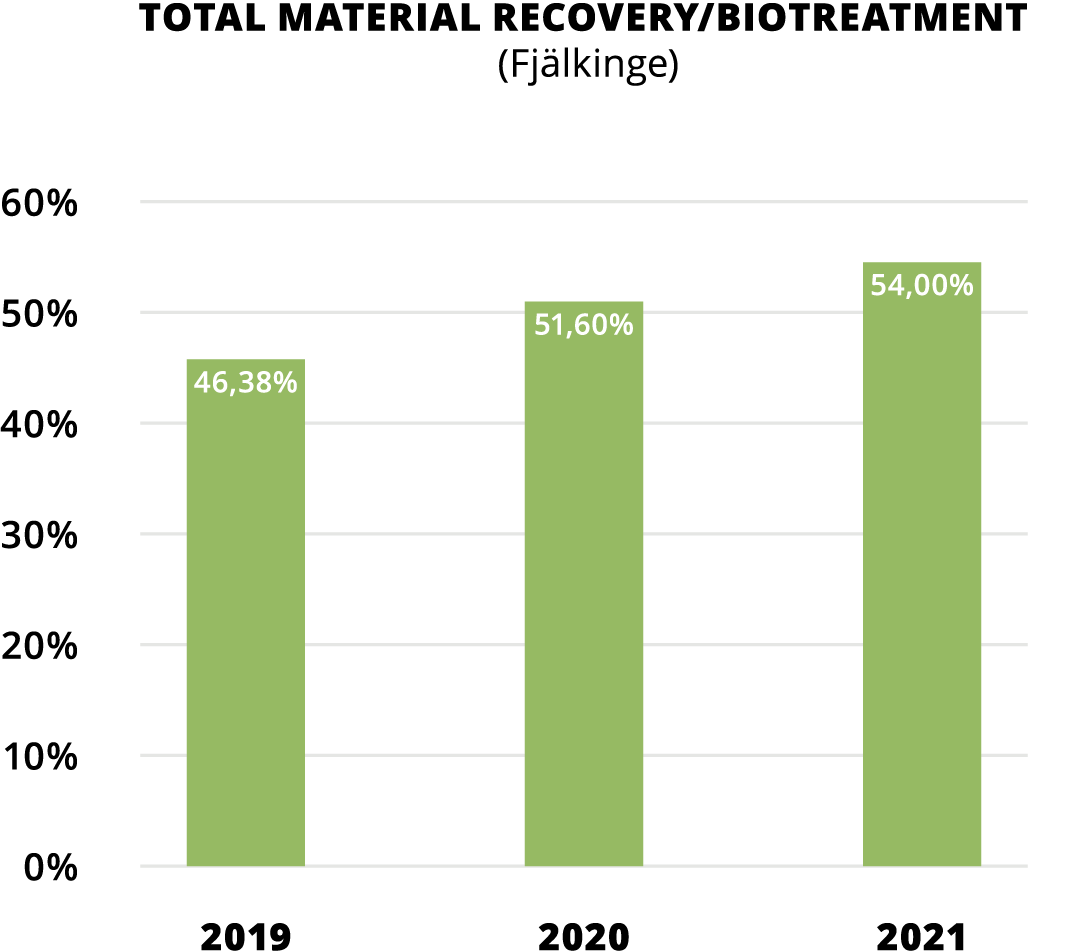

As part of a drive to optimize our use of resources in production, we have worked since 2020 to increase material recovery in our production at Fjälkinge, by introducing more material recovery fractions.

In 2021, we sorted a total of 203 tonnes, and in the first eight months of 2022, material recovery fractions have accounted for 134 tonnes. The goal is for more than 50% of waste to fall into the Material Recovery, Bioprocessing, and Reuse fractions. In total, after eight months of 2022, we are at 54.9%. The goal will be reviewed upwards to reflect our ambitions.