Climate action in starch production

Starch production is an energy-intensive operation, and consequently energy and climate action are extremely important in our sustainability process. We calculate our carbon footprint annually, and have achieved significant reductions of our direct emissions through energy efficiency measures and a transition to renewable fuels.

Prepared for major energy gains

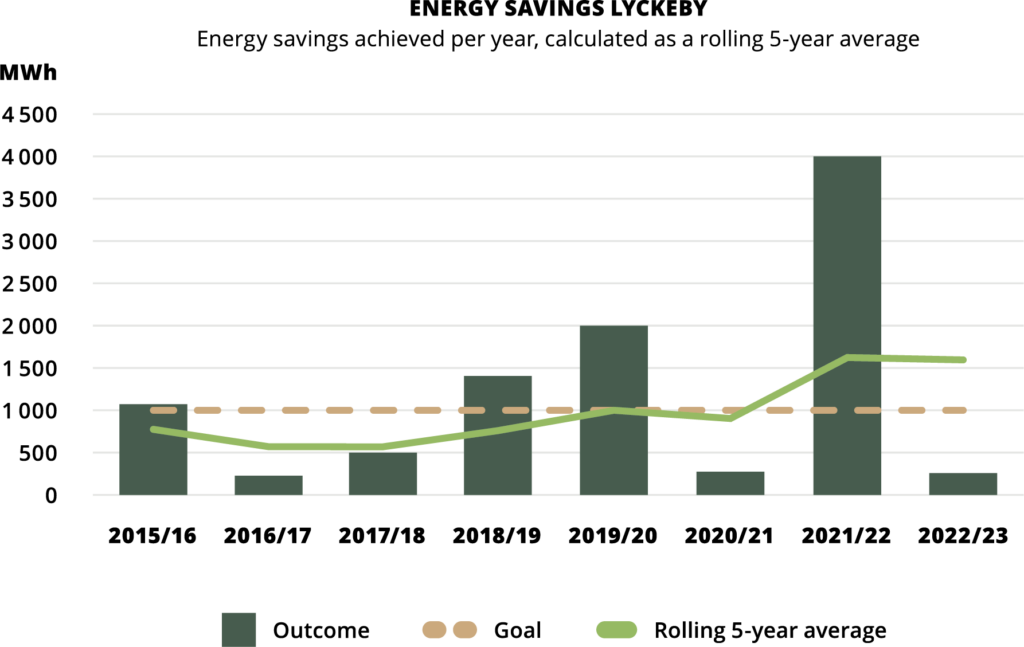

Optimizing energy use is the foundation of useful climate action, and the focus on energy saving is intensifying in line with the major challenges facing the Swedish energy system. Our target is to make energy savings of 1 GWh/year calculated as a rolling five-year average.

Last year we made very extensive energy efficiency measures, and this year too we have taken a clear step despite working hard to adjust an entirely new facility in Mjällby that was commissioned in September 2022.

The new facility, where we now produce almost half of our commercial starch, has an energy consumption that’s around 10% lower per tonne of commercial starch, which adds up to many kWh in total. This is achieved above all through heat recovery from the drying process, but we have also optimized the system based on 20 years’ experience of the process.

This was an opportunity for us to start again from the beginning so we have been able to design the facility from a totally different perspective, which for example means we can make cross-connections between different processes and use more efficient pumps. All of these small optimizations together produce a big effect.

We have also invested in installing more meters in our facilities, which makes it easier for us to work with more automated trends and analysis. And with a control system that allows everyone in the company to connect and look at the information, more people can help improve the process.

* We have chosen to set a target of absolute savings rather than energy consumption per produced tonne so we can more clearly see the total effect of our measures. Our energy consumption varies a great deal depending on the product mix we are producing, which means an efficiency target is not always appropriate.

Emiel Eggenkamp

Mjällby+

The new facility, where we now produce almost half of our commercial starch, has an energy consumption that’s around 10% lower per tonne of commercial starch, which adds up to many kWh in total. This is achieved above all through heat recovery from the drying process, but we have also optimized the system based on 20 years’ experience of the process.