Lyckeby

Development of the starches of the future

The functional food starches of the future

The overarching focus of development work at Lyckeby is on developing products, processes, and concepts that will contribute to our sustainable development. This involves creating new starch products manufactured with lower energy and chemical inputs, and which contribute to creating climate-smart, healthy, and safe food.

A number of long-term research and development projects in the Swedish starch operations are collected under our internal development vision “The green starch factory”. We want to create sustainable products that correspond to our customers’ needs – and ultimately those of the consumer. One major challenge is creating starch products that can cope with the food industry’s demands for process- and storage-stability while simultaneously meeting the increasingly conscious consumer’s demands for the products.

Lyckeby Careful – clean label

Today’s consumer constantly demands more sustainable products, and our Lyckeby Careful portfolio has been created especially to respond to this demand.

The products are processed using a climate-smart production technique patented by Lyckeby. With this technology, we reduce the consumption of energy and chemicals in the processing of process-stable starch products, which are especially designed to tolerate the food production process they are then used in. In addition to the products having a lower carbon footprint, they are also what are known as “clean label” starches, which means that they are declared without E numbers in the ingredients list on the food.

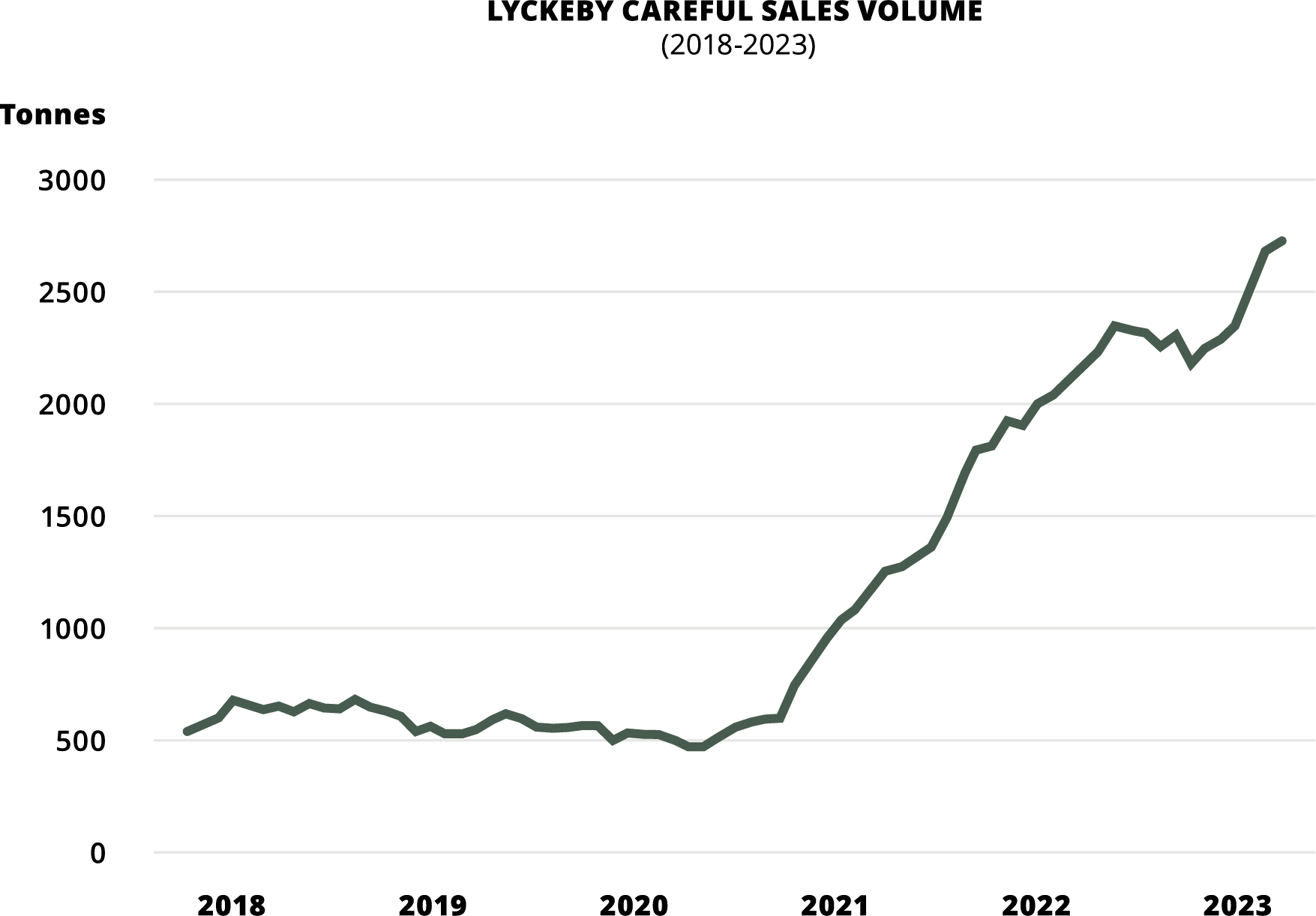

Over the last few years, we have invested in potato-based Lyckeby Careful products with the function of giving consistency, texture, increasing the switch to plant-based meat alternatives, and improving crispness in foods such as French fries. Our goal is to increase sales of Lyckeby Careful tenfold between 2020 and 2025.

Modern plant breeding – changing the landscape

We are extremely proud of our innovation project, in which we have worked with the Swedish University of Agricultural Sciences (SLU), using modern plant breeding techniques and taking a very large step towards creating climate and environmentally-smart food starches.

With the help of the Nobel prize-winning CRISPR-Cas9 genome editor, we have developed new potato varieties whose starch is naturally more storage-stable. Natural storage stability means that smaller quantities of chemicals and thus of energy are required to produce the starch products our customers demand.

During the financial year 2022/2023, we have carried out cultivation of different variants of seed potatoes developed using the genome editor to facilitate future industrial cultivation.

We have also continued product development to evaluate how the starch functions in different food applications, to prepare for a forthcoming product launch. If the project continues to show positive results, we estimate that large-scale production of new climate-smart starch products will be possible in 2025. We are keeping a close eye on the development of regulations on modern plant breeding techniques within the EU. On 25 July 2018, the European Court of Justice decided to regard as GMOs organisms obtained by modern techniques for plant breeding such as CRISPR Cas9. This is despite the fact that modern technologies can be used more safely and more effectively than “traditional” editing methods, which are exempt from the legislation. The decision has been criticized by authorities, researchers, and industry within the EU, and we are continuing to provide information at regional and EU level on the need for and benefits of modern technologies, for example through our project for climate-smart food starches. We expect that the legislation will soon be changed, so we can use modern plant breeding technologies on equal terms with countries outside the EU.

Since the EJC verdict in 2018, the European Commission has carried out an investigation of current legislation and how it should be possible to use modern techniques without jeopardizing food safety. In July 2023, the European Commission released its report, suggesting changes to the GMO directive so that it is possible to use the modern plant breeding technologies such as CRISPR-Cas9. In its statement, the European Commission was clear that the modern plant breeding technologies are necessary for us to be able to achieve our goals within Farm to Fork and The Green Deal. We welcome the European Commission’s position and hope now for a rapid process to decide on a new directive so we can market the new, climate-smart starch products and then continue working on exciting new projects within modern plant breeding.

Kalle Johansson

Collaborative program for innovative food crops

SLU Grogrund is a collaborative program between the Swedish University of Agricultural Sciences (SLU) and industry, which aims at ensuring access to new plant varieties adapted to Swedish growing conditions and contributing to a growing, sustainable, and profitable production of food in Sweden. The program began in 2018 as part of the Swedish food strategy. Participants include academic researchers, plant breeders, and actors from the food and agriculture sectors and society as a whole.

Lyckeby plays an active role in SLU Grogrund’s steering group, and took part in 6 of the program’s 21 projects during 2021.

Dextrin – a natural, E number-free starch with many applications

We produce dextrin in our Czech operations. Dextrin is modified physically rather than chemically, using acid and heat, and is thus declared without any E number in the ingredients list, in the same way at the Lyckeby Careful products.

This starch product is often highlighted as a health product and can also replace egg in some applications. Dextrin can also be used as a replacement in polymer dispersions (plastics) in different technical applications, including during the manufacture of adhesives. Dextrin-based adhesives are used in large quantities in the manufacture of paper sleeves, and today more and more customers are looking for sustainable adhesives for other products and packaging.