Efficiency in our Czech operations

Wastewater, energy, and hydrochloric acid in focus for our Czech starch operations, and efficiency is the keyword in our Czech flavor operations.

Wastewater, energy, and hydrochloric acid in focus for our Czech starch operations

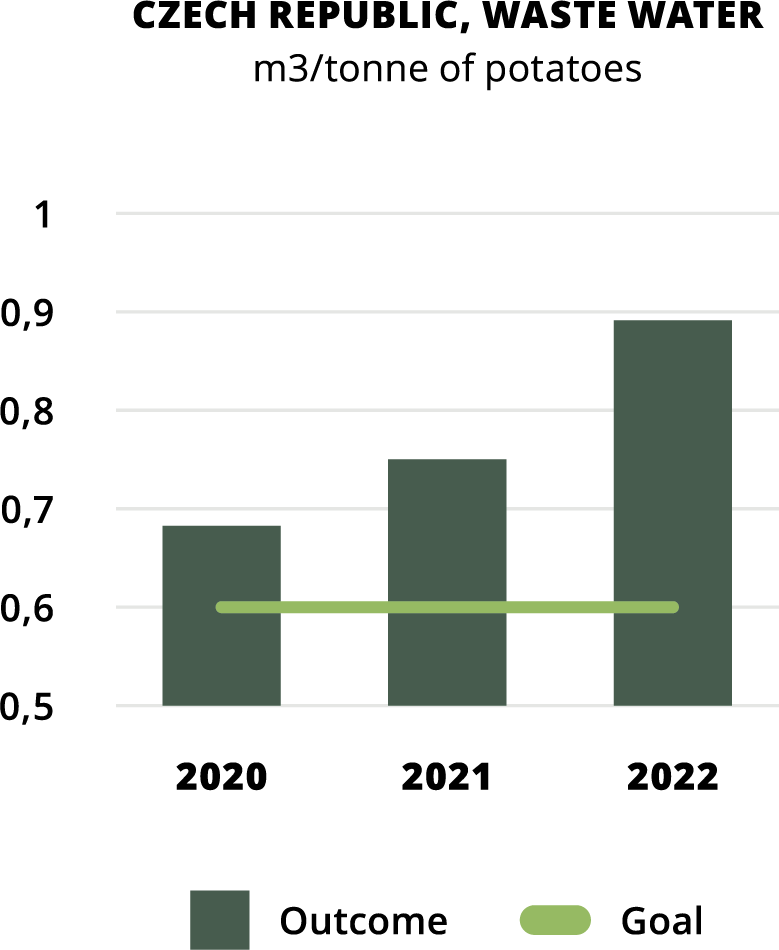

For legal reasons, we don’t have the same opportunity in our Czech starch operations to allow local farmers to use the washing water and potato juice for watering their crops as we do here in Sweden. Instead this water is treated, first in our own treatment plant and then in the municipal treatment plant. Between 2017 and 2021, we invested in reducing the organic material in the wastewater and also obtained two new by-products – protein and fertilizer that can be used in organic cultivation. Our goal now is to reduce the wastewater volume per tonne of potatoes by 30% by 2026, with FY23 (0.86 m3/tonne potatoes) as the base year.

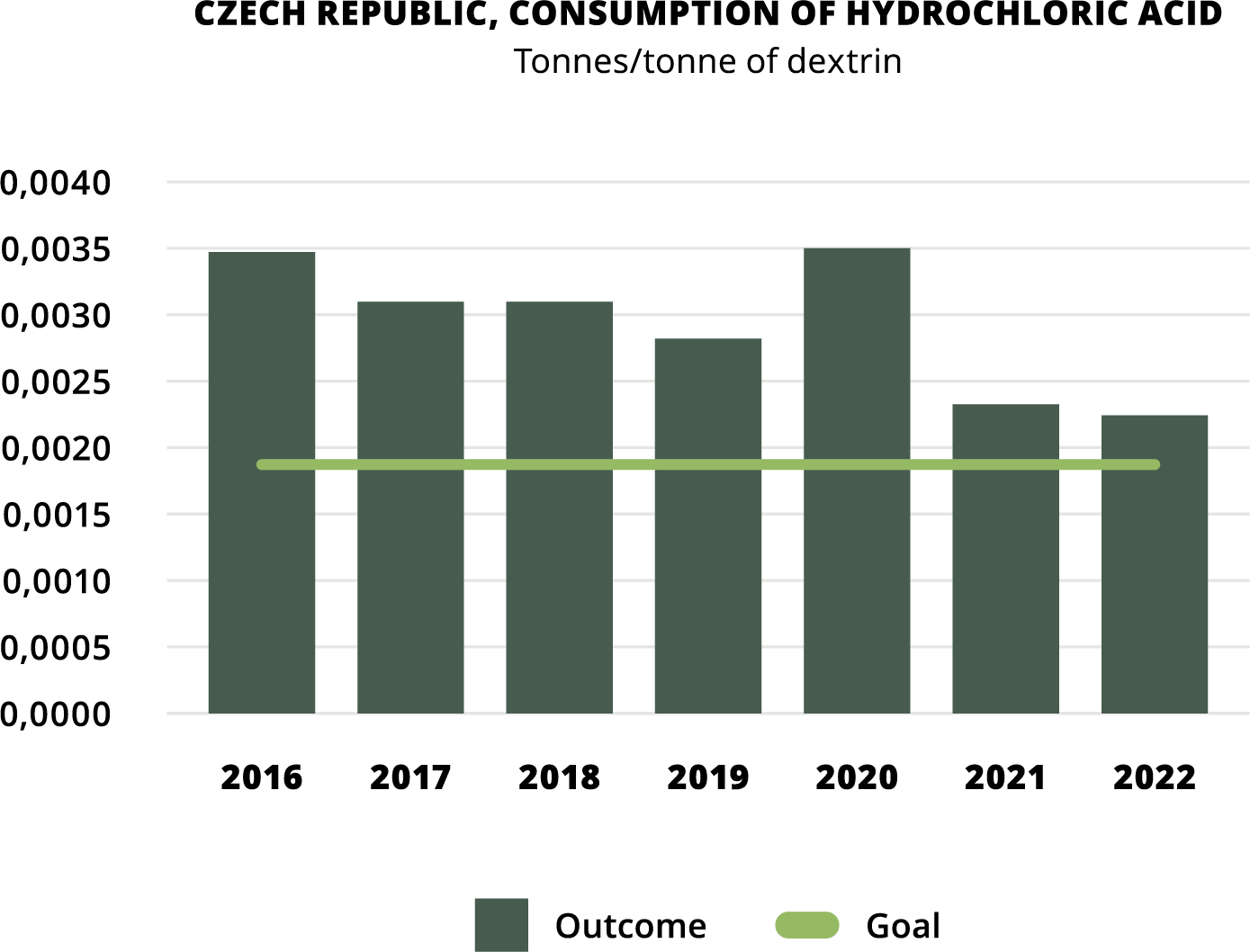

We are also actively working to reduce the use of hydrochloric acid, which is an important input product in the production of dextrin. The dosage is being optimized, and the goal is to reduce use per produced tonne of dextrin by 40% by 2026, compared with the average use for the period 2016–2020. The trend looks positive, and thus far our use has reduced by 34%. Energy use in the process is largely linked to product volume, and we have consequently set an energy goal to reduce energy use during storage of the products. The goal is to reduce energy costs by 10% and we intend to achieve this by investing in a new warehouse.

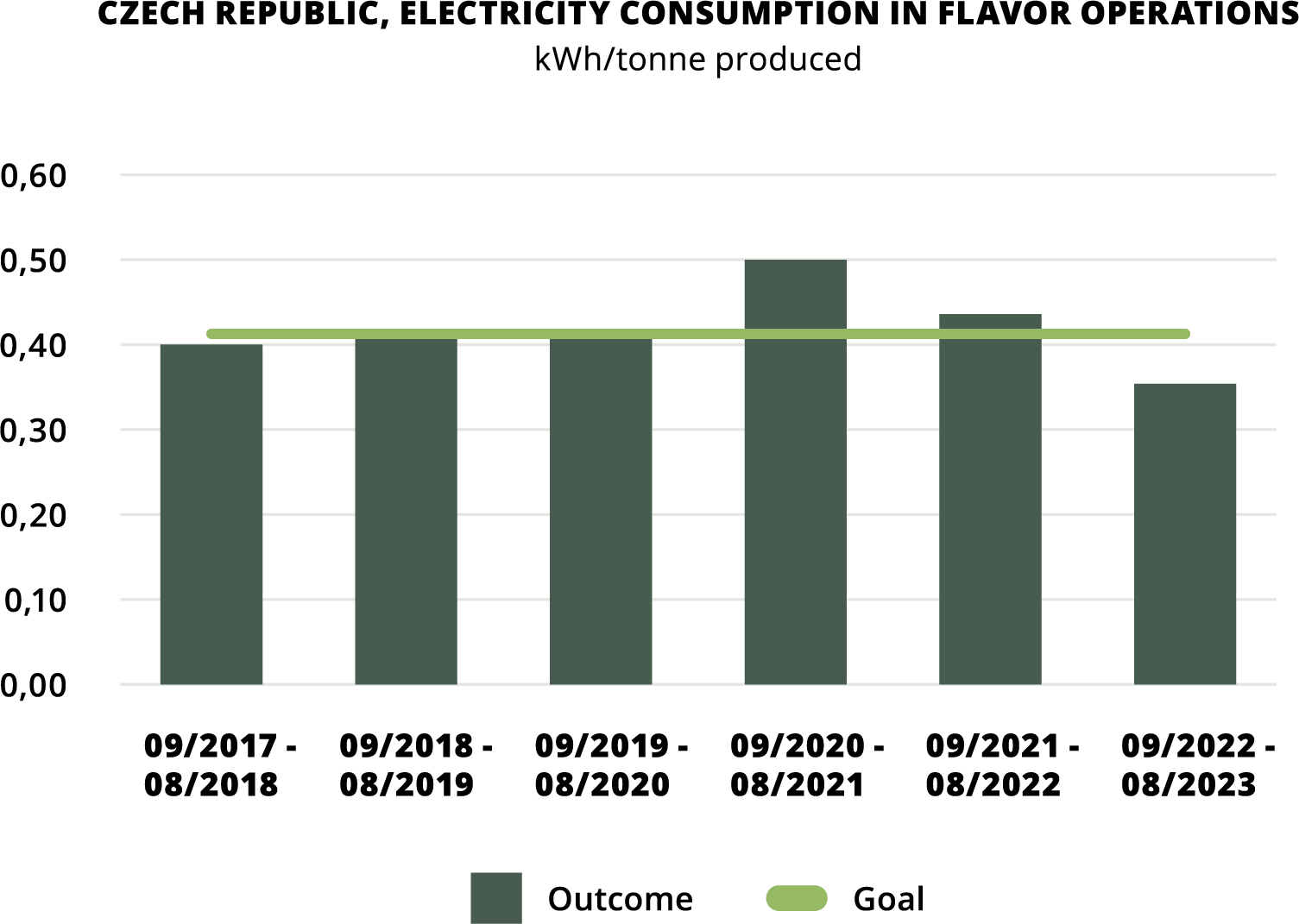

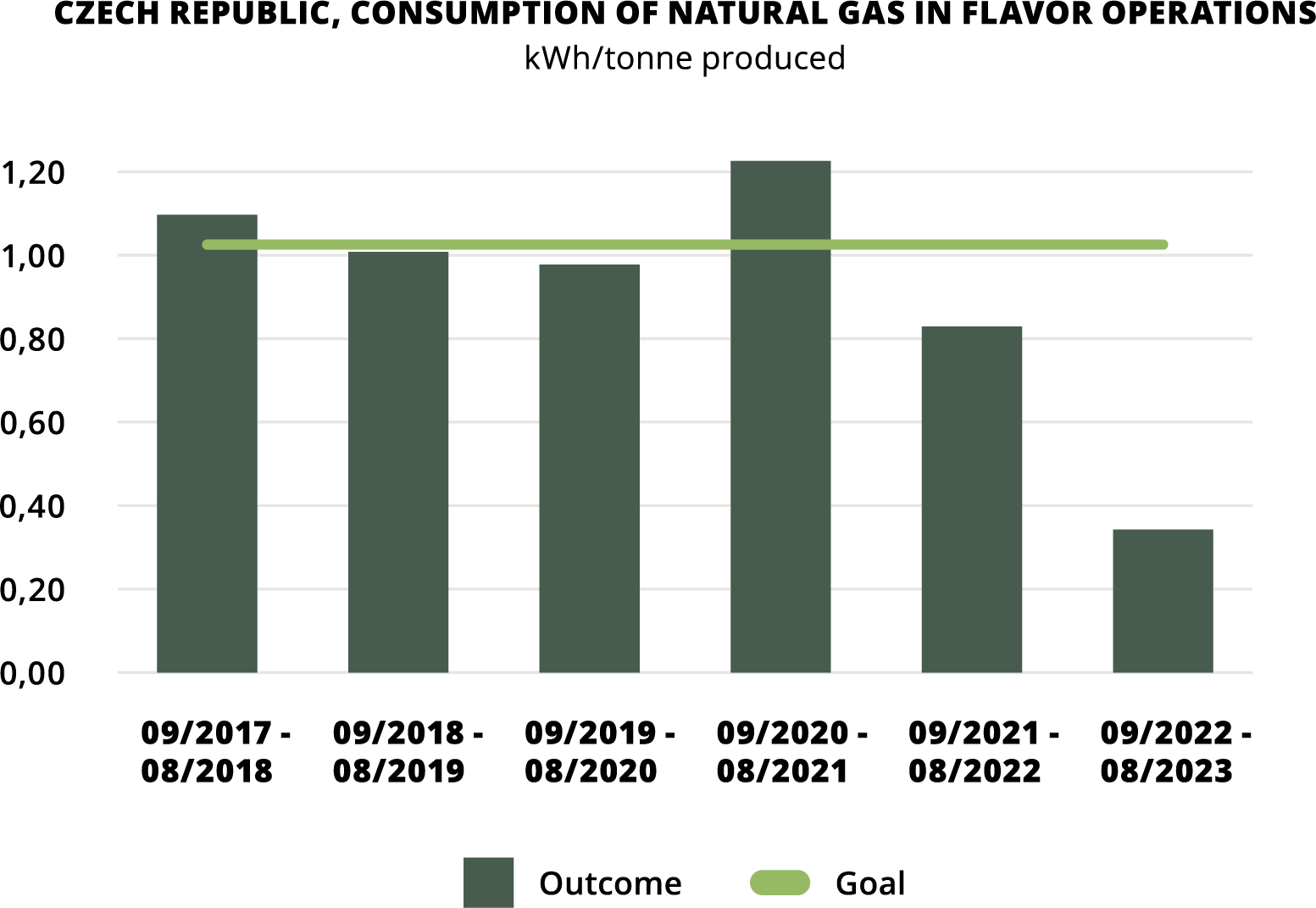

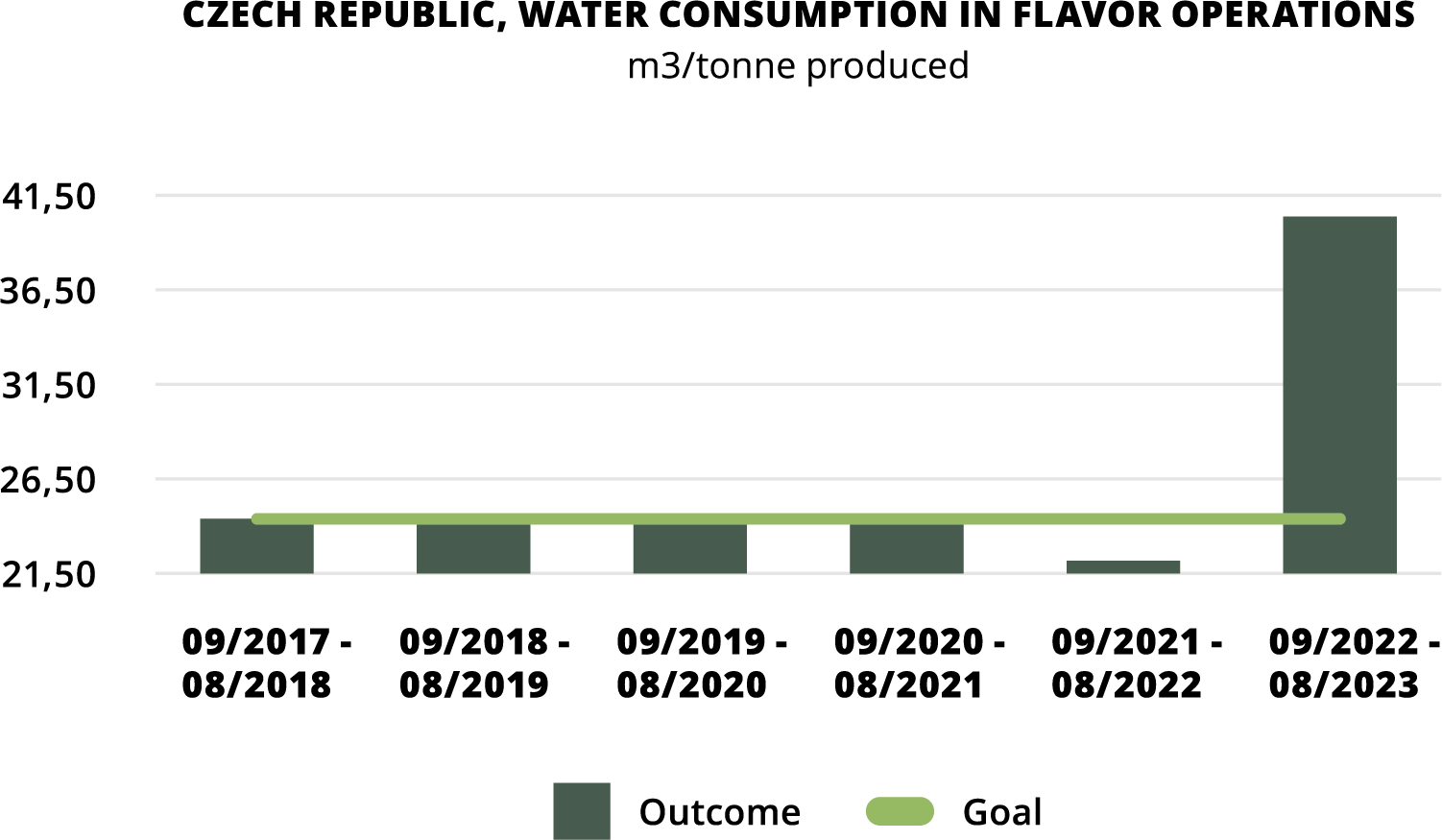

Efficiency is the keyword in our Czech flavor operations

Like the Swedish flavor operations, the Czech organization is focused on energy, but also water. In recent years, efficiency has increased both for energy and water, and the work continues to find opportunities for improvement. We have recently installed solar panels for hot water and a heat pump to heat the warehouse.

Waste from the operations consists of empty packaging, and the wastewater from washing production equipment passes through a particle separator before being piped to the municipal treatment plant.