Energy efficient lighting in our flavor operations

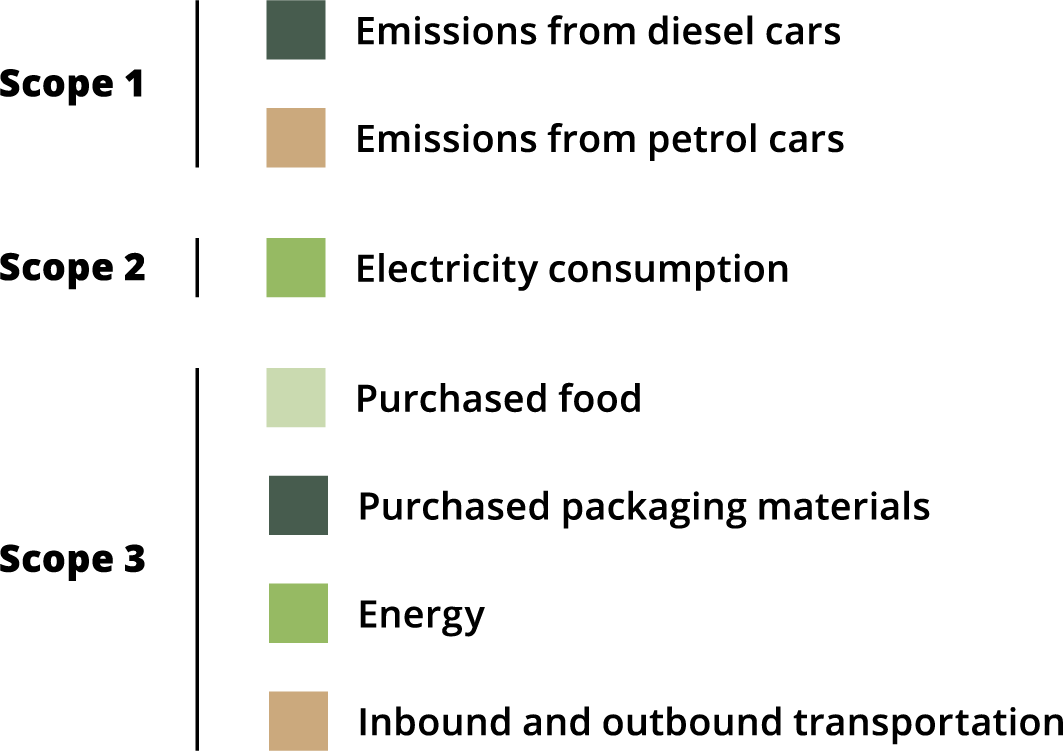

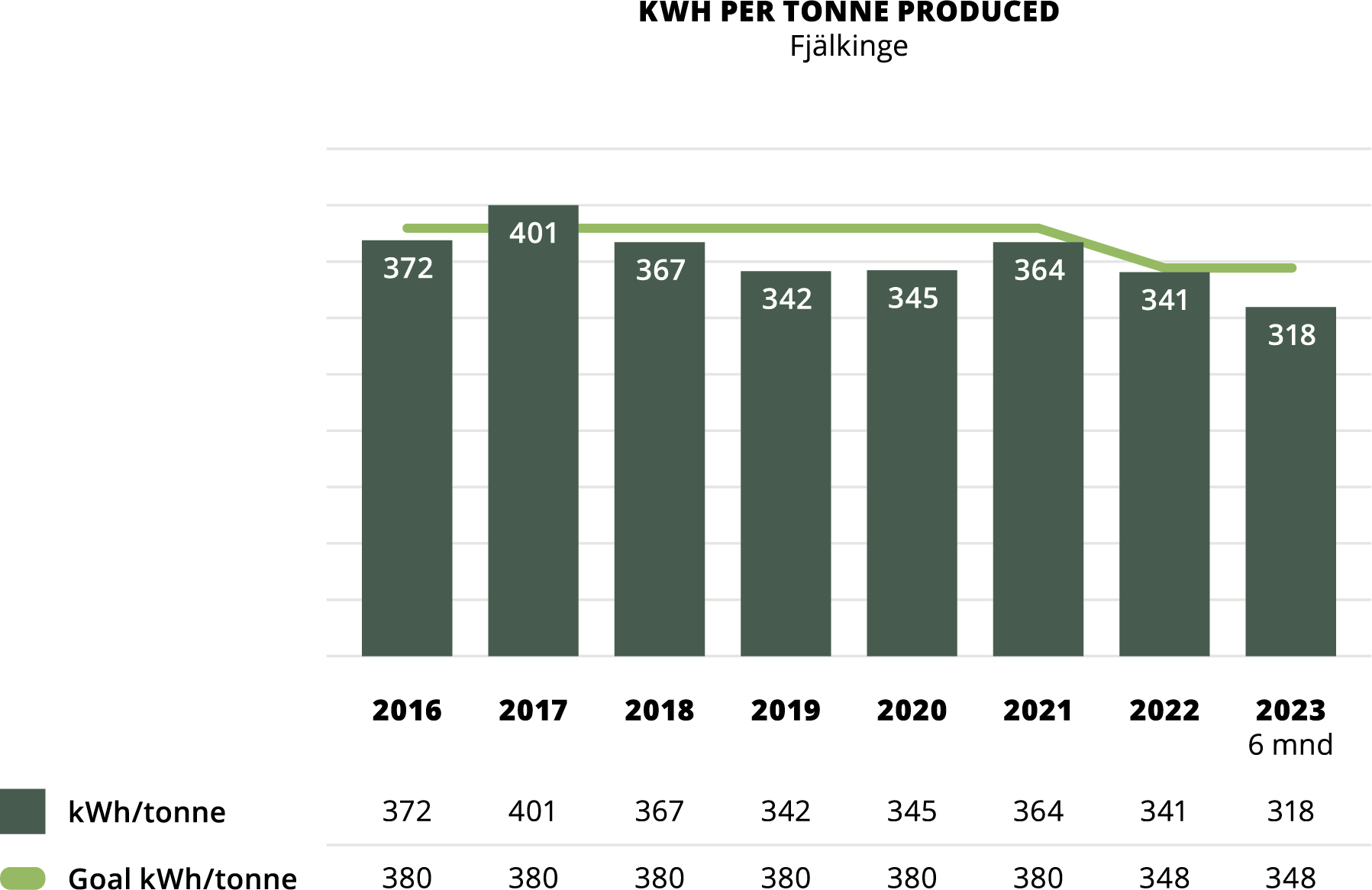

Processing on the flavor side requires much less energy than the starch process, but despite this it is, of course, important for us to reduce our energy use and we work with continuous improvement of our energy efficiency through a structured energy management group. During the year we have installed around 100 new high-level LED luminaires with movement sensors in our warehouse and we continue to replace the older LED luminaires with newer generation LEDs. These measures meant that last year we achieved our energy efficiency goal (348 kWh/tonne). Energy consumption per produced tonne was thus 14% lower than in 2015. We have chosen to retain the same goal in 2023 and will evaluate it in the energy management group in January 2024.

First carbon footprint in place for the Swedish flavor operations

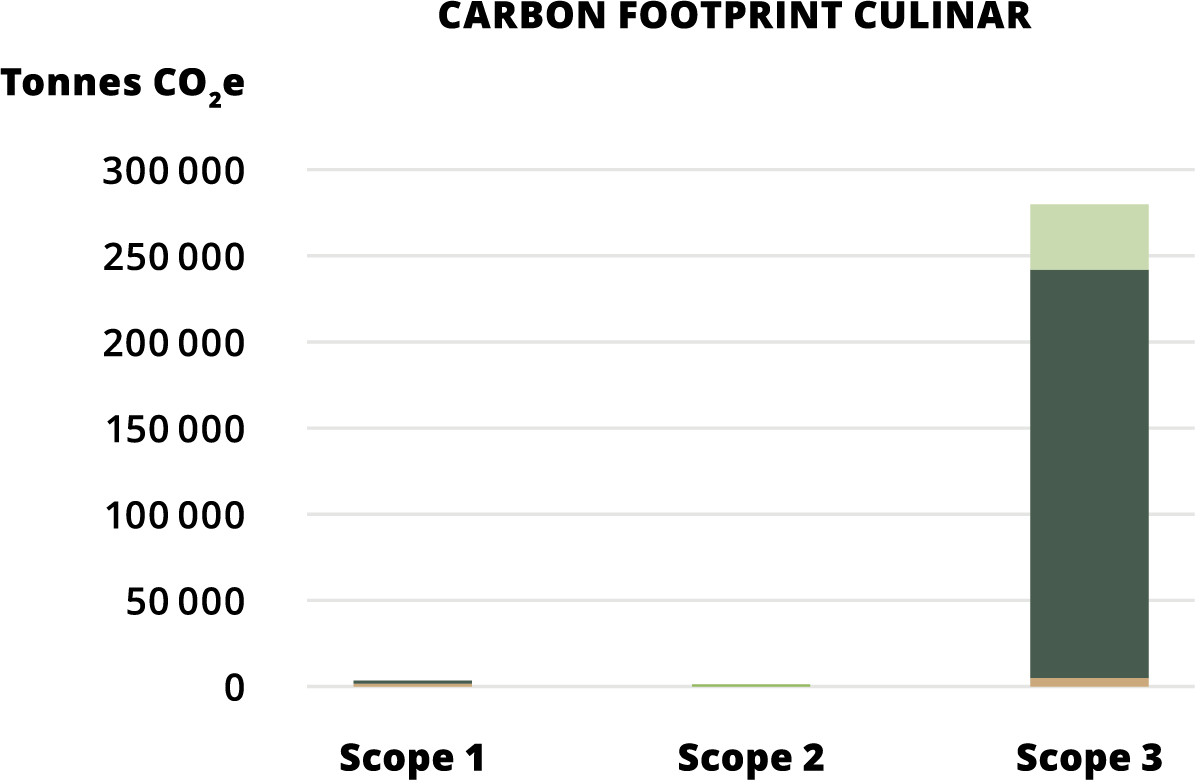

To better understand what we should focus on in our flavor operations’ climate work, we have now carried out a calculation of our flavor operations’ carbon footprint in Scope 1, 2 and 3 according to the Greenhouse Gas Protocol. All the energy we use for our own production in the Fjälkinge factory has been fossil-free since January 2019, and the total carbon footprint for Scope 1 and 2 for 2022 (primarily emissions from cars) represents less than 1% of the total. The analysis clearly shows that our work with climate-smart packaging is definitely the right priority. Read more about this on page 66. For Kockens’ products, we have signed up to DLF’s 2025 Transport Initiative, a voluntary commitment and a clear statement that the grocery industry wants to drive development towards fossil-free transports. This means that we have a goal of fossil-free transports for Kockens products from 2025. We have also joined the Swedish Food Federation’s Sustainability Manifesto, where one of the five commitments is “A fossil-free industry”. In line with this manifesto, we are aiming to use only fossil-free fuels for transports of Culinar products by 2030.

Resources in focus

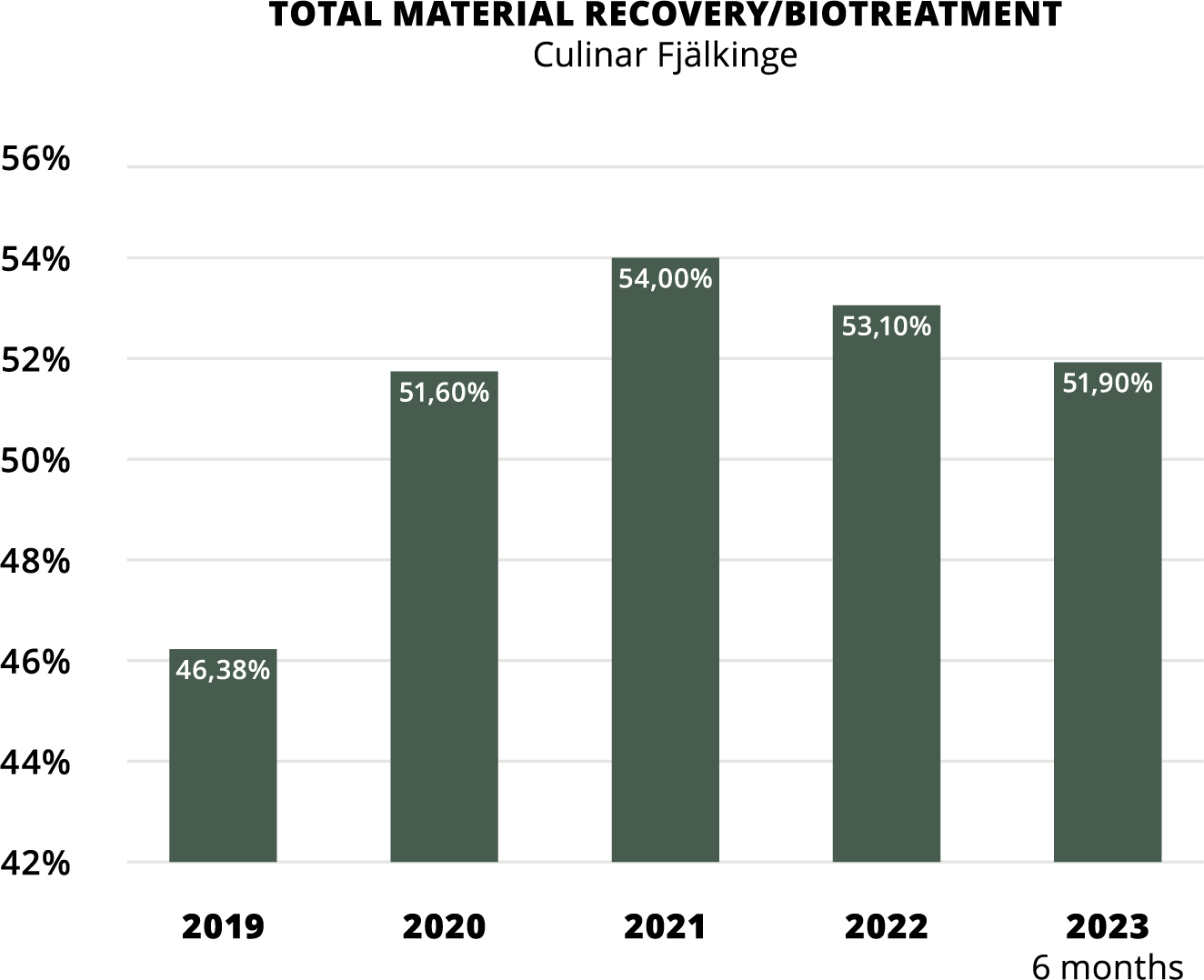

As part of a drive to optimize our use of resources in production, we have worked since 2020 to increase material recovery in our production at Fjälkinge, by introducing more material recovery fractions. Our KPI is for more than 50% of waste to fall into the Material Recovery, Bioprocessing, and Reuse fractions. Between January 2020 and June 2023, we introduced four new material recovery fractions (Mixed Paper, Hard Plastic, LDPE Colored, and PP Bigbags). These fractions have allowed us to sort waste from the combustible fraction to the new fractions, and together this has increased our material recovery by approximately: 6%. In total for these fractions, we have sorted 143 tonnes (2020–2023) which would otherwise have gone into the combustible fraction. For all material recovery fractions, we have thus far sorted 94 tonnes in the first six months of 2023. During fall 2023 we will investigate the opportunity for taking a new step on the waste staircase, and moving some waste from energy recovery to reuse.