Sveriges stärkelseproducenter

Sustainability

Everything we do at Sveriges Stärkelseproducenter originates in nature. To us, it feels obvious that we should do everything we can to promote environmental well-being.

This year in brief

Hans Holmstedt

Welcome to our sustainability report!

At Sveriges Stärkelseproducenter, we work with our Lyckeby, Solam, Culinar, and Kockens brands in a global market. We come from nature, with our roots in potato cultivation and many agricultural products as raw materials.

So for us it’s essential to minimize our impact on the Earth’s resources and to always act with great respect for humans, animals, and nature.

Sustainability is a self-evident aspect of our business and our processes. We work with sustainability every day, and it guides our choices both in our current ways of working and when we choose future developments and priorities.

About Sveriges Stärkelseproducenter

Sveriges Stärkelseproducenter is an agricultural cooperative founded in 1927. The association has 600 members in southern Sweden, of whom 400 are active growers of our primary raw material – starch potatoes.

The association has two business areas: starch and flavor. Our starch operations are run under the name Lyckeby, while flavor is managed by the companies Lyckeby Culinar AB (Culinar) and Kockens AB (Kockens). In total, the association employs around 350 people in Sweden. Turnover is approximately 2.5 billion kronor.

Our vision

Starch potatoes are the most profitable option for our growers.

Starch

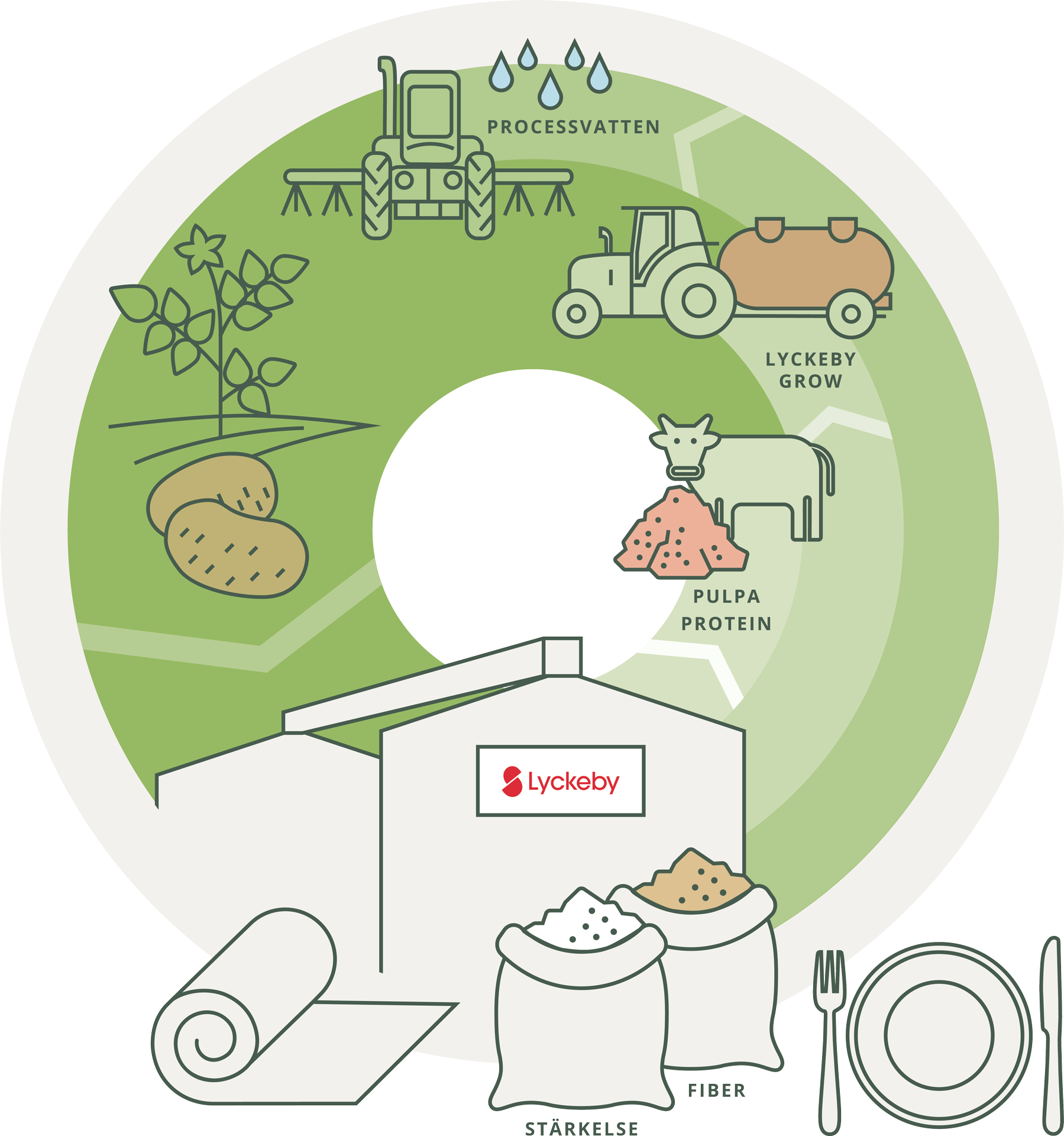

We produce starch from potatoes grown by our owners, and transform it to suit our customers’ needs and requirements.

The process water from production is returned to the fields to water the crops

Our main raw material is starch potatoes grown by our owners

Soil and stones from potato deliveries are used as fill materials, for example during road construction

We refine starch into starch for the paper industry

The potatoes delivered to the starch factory are fractionated into starch, fiber, and protein

The starch and fiber are also refined into value-added products for the food industry

The plant parts remaining after the food-grade fiber has been processed are concentrated into pulp and sold as feed. Also the potato protein is refined into a nutritious feed product

The nutrients in the potato juice are concentrated and sold as fertilizer

Starch operations

We buy potatoes from our owners and potato growers, processing and utilizing the material in the best possible way so we can offer customized, functional potato starch products to customers within the food and paper industries.

We focus on markets and applications where potato starch has high potential, giving our customers added value. When you buy from Lyckeby, you always get support and knowledge within the areas of product development, applications, logistics, and quality, from our highly experienced team.

In addition to adding value to the starch, we also make use of side streams, creating sustainable production with high circularity. The potatoes delivered to the starch factory are fractionated into starch, fiber, and protein. The starch and fiber are refined into our main products, but we also make use of the by-products.

This means that our production is a good example of a circular system where the majority of the raw materials are utilized in a resource-efficient way. In our factories we also work continuously to ensure that fractionation, purification, and processing use the least possible input in the form of energy and chemicals.

Lyckeby

Sveriges Stärkelseproducenter offers customized, functional starch products and potato fiber to the global food industry under the Lyckeby brand.

Solam

Sveriges Stärkelseproducenter sells value-added starch products to the paper industry in Europe under the Solam brand.

Flavor

We blend spices with other ingredients to create products that simplify customer logistics.

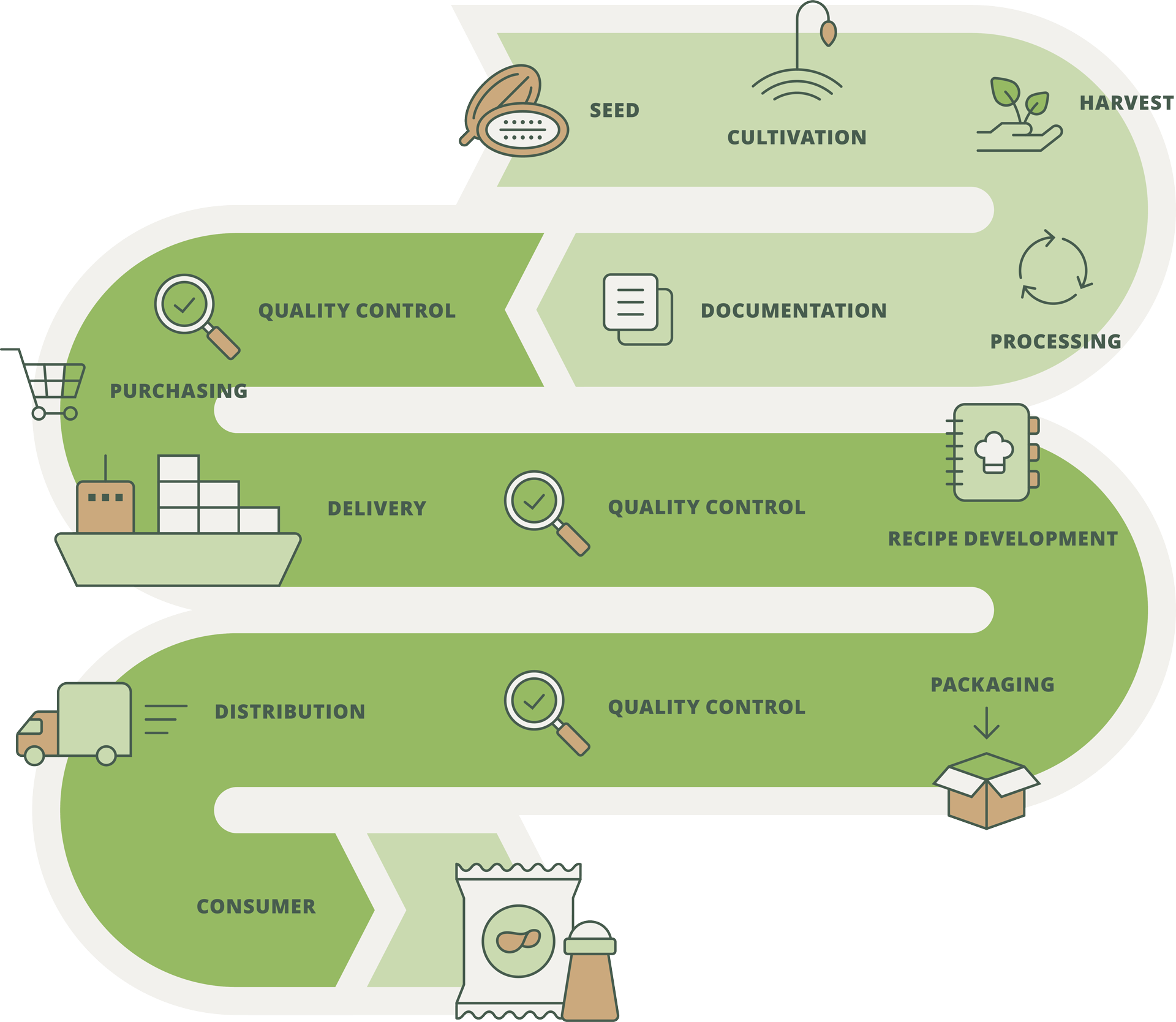

Seed

Cultivation

Harvest

Processing

Documentation

Quality control

Purchasing

Delivery

Quality control

Recipe development

Packaging

Quality control

Distribution

Consumer

Flavor operations

At Culinar, we blend spices from all over the world with other functional ingredients (including Lyckeby’s potato starch) to create ready-to-use flavor and texture ingredients for the food industry. Our role in the value chain is to simplify and streamline logistics and blending in the customer’s end process.

Contributing support and knowledge within applications such as snacks, meat and deli, bakery, etc., is an important part of our business. Here we collaborate closely with the customer so the consumer receives a good end product As well as application knowledge, we also optimize packaging and manufacturing to minimize waste and simplify handling of ingredients by the customer.

At Culinar, we also create products that are sold directly to the consumer and to the catering industry via Kockens.

Culinar

Lyckeby Culinar AB offers a wide range of spices, other ingredients, and unique blends to the food industry in Europe under the Culinar brand.

Kockens

Kockens AB creates products targeted at consumers and the catering industry in Sweden under the Kockens brand. The products are dried herbs and spices, potato starch, and gluten-free flour.

Our production units

Sveriges Stärkelseproducenter has five production units in Sweden, all located close to where our starch raw materials are grown. Click on the map pins to read more!

Our sustainability process

Sveriges Stärkelseproducenter’s business has a clear place in a sustainable future, but just like every other enterprise we need to constantly develop our way of working to minimize negative impact and maximize business benefit. We have chosen to focus our sustainability efforts within four main focus areas we feel are most relevant from a risk and impact perspective.

These focus areas are common to our two business areas, and follow our value chains, centering on the processing of cultivated raw materials. By working with these focus areas, we can contribute to a more sustainable world. We present here our focus areas and the Agenda 2030 goals we link to our sustainability process.

A value-adding workplace

Our workplaces should generate value in the form of security, satisfaction, diversity, and equality for everyone working there. The foundation of this approach can be found in Swedish legislation and is reinforced by our corporate culture, which is characterized by commitment, pride, and loyalty.

Sustainable cultivation

Our primary raw materials are cultivated crops. Around the world, cultivation faces a range of challenges within areas such as biodiversity, climate impact, and social conditions. We aim to meet the relevant challenges with knowledge and responsibility.

The products of the future

Together with our customers and collaboration partners, we work to develop the sustainable products of the future, which will contribute to both improved health and a better environment.

RESOURCE-EFFICIENT OPERATIONS

Through careful processing of the starch, and making use of side streams, we create sustainable production with high circularity. We also work continuously in our factories to ensure that all production takes place with the least possible input of energy and chemicals.

We prioritize long, strong, and transparent relationships with our customers. By offering high levels of support within sales, logistics, product development, and quality, we create further security both in our customers and our own employees, laying the foundation for good business and shared confidence. This also gives the customer the opportunity to impact our development as a sustainable company.

Mathias Samuelsson

A value-adding workplace

The COVID pandemic has led to an acceleration of our digital way of working, and we are thankful that we invested in new equipment for digital meetings immediately before the pandemic arose. Today, many of our meetings with customers and collaboration partners take place digitally, and we have also begun offering webinar training sessions for our customers.

André Nordgren

A value-adding workplace

Naturally, the employees are the motor of our business, and they deserve a workplace that generates value in the form of security, satisfaction, diversity, and equality. To contribute to our sustainable development, they also need the right skills to address future opportunities and customer challenges.

We are a Swedish company and the way we treat our employees is based in Swedish legislation, Swedish practice, and central collective agreements. We are members of the Confederation of Swedish Enterprise and the Swedish Food Federation – an employer organization – and these memberships ensure we remain informed about the Swedish labor market, and that we act in line with industry practice. Beyond this foundation, we have local agreements and policies for terms and conditions, regulations, procedures, etc. We want to be an attractive employer for both new and existing employees.

Marcus Nilsson

New control room for better working environment and collaboration

In 2021, as part of the ongoing Mjällby Plus project – Lyckeby’s largest investment ever – a new control room was constructed at the Mjällby factory, replacing three former control rooms.

Operators for all processes in the factory now work in the same space, which makes collaboration and problem-solving during operation much simpler – and in addition creates a more pleasant working environment.

The control room is now also much quieter, equipment and systems have been updated, and the workstations are more ergonomic.

KPI overview

Here we provide a summary of the KPIs we follow in our sustainability work, and how close we are to achieving our goals.

Sustainable cultivation

For us, it’s essential to ensure traceability in our almost 1000 different raw materials, and to work towards improved social conditions in our supplier chain.

Khirim Fager

Sustainable cultivation

Flavor

We purchase raw materials from all over the world, which represents a significant challenge in the form of guaranteeing food safety, cultivation conditions, working conditions, human rights, and environmental impact.

Flavor development area

Starch

Potatoes for our starch production are cultivated locally in southern Sweden. Our primary challenges are minimizing the use of plant protection products while maintaining yields, and limiting the climate impact from cultivation.

Starch development area

Paulina Norup

KPI overview

Here we provide a summary of the KPIs we follow in our sustainability work, and how close we are to achieving our goals.

Resource-efficient operations

Our focus on energy savings is having an effect! We are proud to have achieved our yearly goal with a good margin.

Kristina Linde

Resource-efficient operations

By making use of side streams and working efficiently, we create sustainable production with high circularity. In our factories we constantly strive to ensure that all operations use the least possible input in the form of energy and chemicals.

Energy efficiency has always been a high priority issue, and our production facilities have been certified according to ISO 50001 for many years. We also continuously develop measurement and monitoring systems for our carbon footprint, in parallel with taking measures to reduce greenhouse gas emissions, for example by replacing fossil fuels in production and transports.

As one aspect of optimizing resource use, we also strive to increase material recovery in our operations.

Development areas

- Energy and climate

- Chemical use

- Material recovery

- Sustainable transports

Jonas Oskarsson

KPI overview

Here we provide a summary of the KPIs we follow in our sustainability work, and how close we are to achieving our goals.

The products of the future

Our offering always includes our expertise and experience to support the customer’s product development. Through close, transparent collaboration, we create the sustainable products of the future – together.

Malin Thors Rosenqvist

The products of the future

Sveriges Stärkelseproducenter’s development departments within both the starch and flavor operations collaborate closely with our customers to develop new products that meet consumer needs. Demand for sustainable solutions in the form of climate-smart options, clean label, plant-based products, and healthier variants is increasing, as too is the demand for transparency in the value chain.

The experts in our development departments have long experience of working with different applications and know which ingredients are required to handle different production processes. We offer support in the development of new sustainable products by helping our customers to choose sustainable ingredients that work in their various applications.

On the starch side, we are also continuously developing our by-products, which is another important aspect of sustainable operational development.

Lyckeby Careful – functional clean label starches

Today’s consumer constantly demands more sustainable products, and our Lyckeby Careful portfolio has been created especially to respond to this demand.

KPI overview

Here we provide a summary of the KPIs we follow in our sustainability work, and how close we are to achieving our goals.