Biofuel for starch production

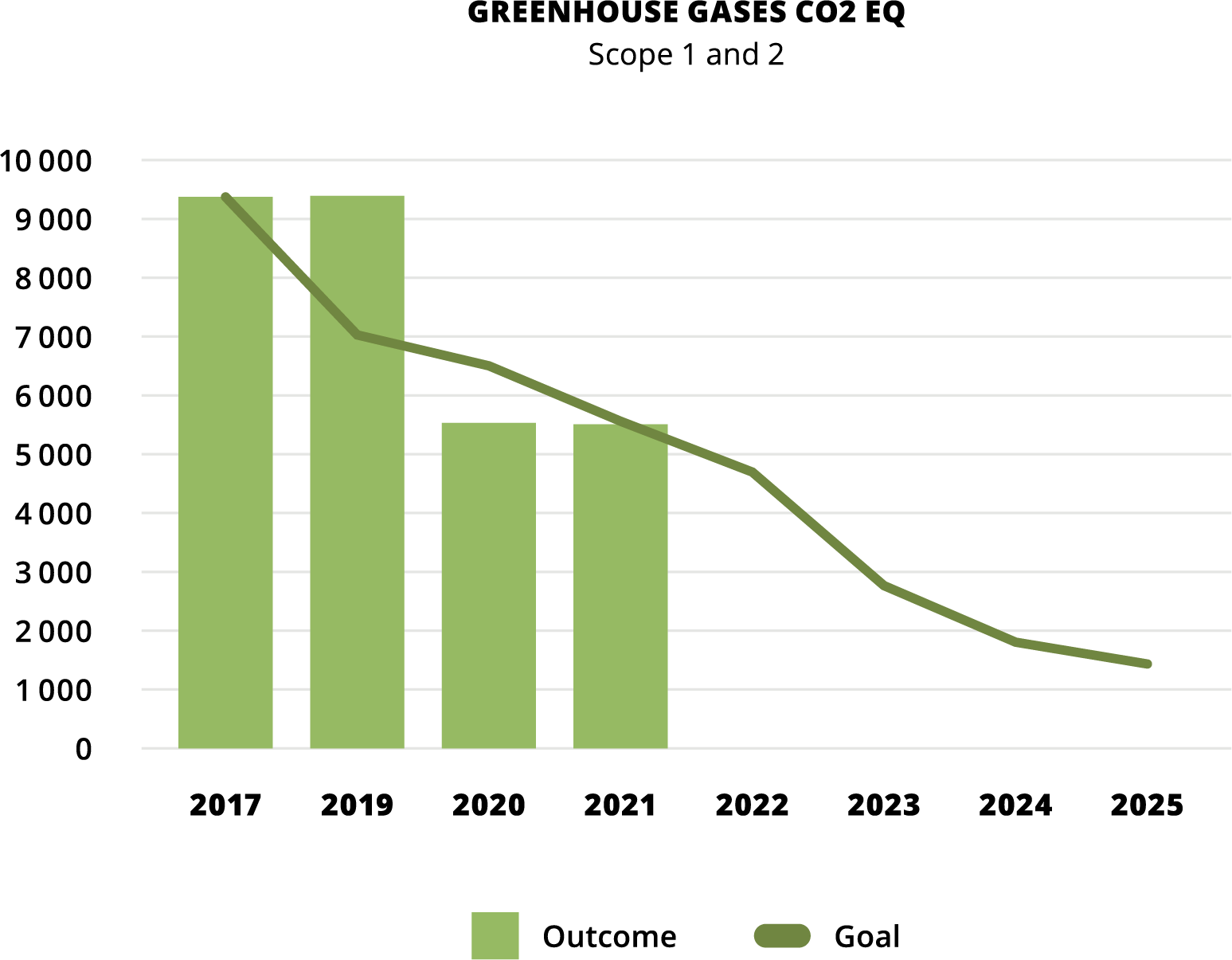

In 2019, when we first calculated the carbon footprint of our starch production (according to the GHG protocol), we realized that emissions from energy for production (Scope 1 and 2 ) made up approximately one third of our carbon footprint. As a consequence of this, we applied for and received aid from Klimatklivet for the transition to renewable fuel.

Since then we have completely phased out the use of fuel-oil, and our use of LPG has been reduced by approximately 95%. Instead we now use bio-oil. This allowed us to reduce our carbon footprint in Scope 1 and 2 by 40% between 2017 and 2021, exceeding our goal by 30%.

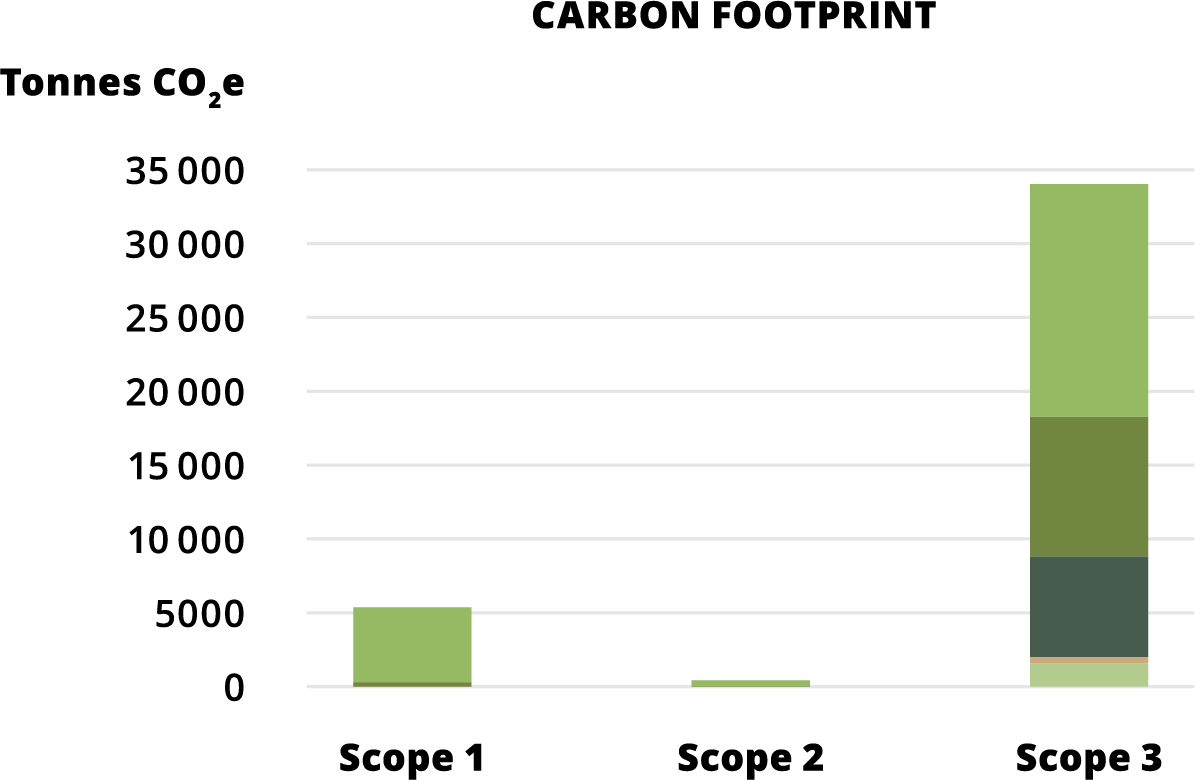

Lyckeby’s carbon footprint (Scope 1, 2, and 3) for 2021. *Emissions from electricity are calculated using the location-based approach, which is the calculation method we use in our metrics. Using a market-based approach, the equivalent result would be 2,992 tonnes of CO2eq. The biogenic emissions were 5,540 tonnes of CO2eq.

In 2021, our emissions of greenhouse gases from energy use in production (Scope 1 and 2) represented approximately 12% of our total carbon footprint.

We have drawn up new long-term strategic goals to reduce our climate impact, and our ambition is to align with the Paris Agreement. Our long-term goal is to reduce Scope 1 and 2 GHG emissions by 85% between 2017 and 2025.

During FY22, there have been shortages of bio-oil, and we have therefore not been able to reduce our carbon footprint as much as planned, but the footprint is similar to previous years despite increased production. Our goal for 2025 is unchanged.